How to Develop a Resilient Supply Chain for Your Business

11 June 2025

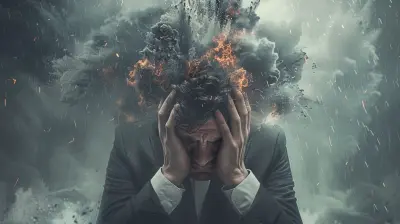

Let’s be honest—talking about supply chains doesn’t exactly light up the room at parties. But if you’re running a business, your supply chain is the quiet hero (or villain) behind the scenes. When things are smooth, you don’t give it much thought. When they’re not… well, it’s chaos.

We’ve seen it all lately: worldwide pandemics, natural disasters, border issues, political drama—you name it. All of this has shown us one undeniable truth:

If your supply chain can’t take a punch, your business is in trouble.

So how do you toughen up your supply chain? How do you make it flexible, adaptable, and strong enough to withstand anything thrown its way?

That’s exactly what we’re diving into today.

What Does a Resilient Supply Chain Really Mean?

Before we dive into strategies, let’s clear the air: what exactly is a resilient supply chain?In a nutshell, it’s your business’s ability to withstand and recover quickly from disruptions. Think of it as your supply chain’s immune system. If it’s strong, a sudden “flu” (like a supplier shutting down or a shipment delay) won’t put you on life support.

A resilient supply chain doesn’t just bounce back—it bounces forward. It learns, adapts, and evolves with every challenge.

Why Should You Care About Supply Chain Resilience?

You might be thinking, “I’ve got reliable partners. We’ve been working together for years. Why fix what isn’t broken?”Fair point.

But what if one of those partners goes out of business tomorrow? What if a storm shuts down a transportation hub? What if demand spikes overnight?

The global business landscape is unpredictable at best. And in fragile systems, even the smallest hiccup can lead to massive ripple effects. We’re talking shipping delays, rising costs, lost customers—and worse, damaged reputation.

If resilience isn’t on your radar yet, it should be.

The Building Blocks of a Resilient Supply Chain

Alright, now that we get the “why,” let’s focus on the “how.” There isn’t a one-size-fits-all recipe, but there are some solid building blocks that work for almost any business.Here’s what you need to focus on:

1. Diversify Your Supplier Base

Let’s start with a classic mistake: relying on a single supplier.It’s like putting all your eggs in one basket and then juggling knives over it. It might work for a while—until it doesn’t.

When you rely heavily on one source (especially if it's overseas), you’re vulnerable to anything that affects that source. That could be political upheaval, factory closures, or even sudden price hikes.

The fix? Build relationships with multiple suppliers across different regions. This way, if one goes down, you’ve got backups ready.

> Tip: Don’t just diversify vendors—diversify regions too. A natural disaster won’t hit all your sources at once if they’re spread out.

2. Improve Supply Chain Visibility

You can’t fix what you can’t see.If you’re flying blind when it comes to your supply chain, you're going to have a hard time spotting problems before they snowball. That’s where visibility comes into play.

Think of supply chain visibility like Google Maps for your products—it tells you where things are, how they're moving, and where the holdups are.

By using real-time data, sensors (IoT), and management software, you can gain clear insights into everything from raw material sourcing to last-mile delivery.

When you know what’s happening at every link in your chain, you can make proactive decisions instead of playing catch-up.

3. Build Strong Relationships with Partners

Business is still, at its heart, about people.Your suppliers, shippers, and partners aren’t just faceless companies—they’re teams of people who can either go the extra mile for you or leave you hanging when things go south.

Invest in these relationships. Communicate regularly. Offer fair terms. Treat them like long-term partners, not just vendors.

When the pressure’s on, the strength of these relationships can make a world of difference.

4. Embrace Automation and Technology

Let’s face it—humans are awesome, but we’re not great at handling millions of moving parts all at once.That’s where technology steps in.

From warehouse automation and AI forecasting to blockchain tracking and predictive analytics, modern tools can help you streamline, monitor, and optimize your supply chain in real time.

Automation not only saves time but also reduces human error and increases your capacity to respond quickly to changes.

> It's like upgrading from a paper map to GPS with traffic updates—you’ll never want to go back.

5. Maintain Strategic Inventory Buffers

A big part of resilience is just being prepared. That’s where safety stock comes in.Now, we’re not saying you should hoard like it’s 2020 again. But keeping some extra inventory of key items can be a lifesaver when there’s a disruption.

Of course, this does require balance. Too much buffer and you’re tying up cash. Too little and you’re out of stock when it matters most.

The goal isn’t overstocking—it’s strategic stocking. Use data to guide how much buffer you need based on demand patterns and risk levels.

6. Scenario Planning and Risk Assessment

You wouldn’t go skydiving without a backup parachute, right?The same logic applies to your supply chain. You need contingency plans.

Start by identifying your weak points. What parts of your supply chain are most vulnerable? Where are the bottlenecks? What would happen if those parts failed?

Then, run through “what if” scenarios. What if demand spikes by 50%? What if your top supplier shuts down?

By walking through these exercises, you’ll be more prepared—and you’ll train your team to think on their feet.

7. Encourage Cross-Functional Collaboration

Your supply chain doesn’t operate in a silo. It touches just about every part of your business—from sales and marketing to finance and customer service.If these departments aren’t talking to each other, you’re going to hit snags.

Foster cross-functional communication. Make sure everyone’s aligned on goals, forecasts, and strategies. The more connected your internal teams are, the smoother your supply chain will run.

8. Prioritize Sustainability

Here’s a truth bomb—resilient doesn’t mean fast and cheap. It means sustainable.Companies that invest in eco-friendly practices, ethical sourcing, and sustainable logistics aren’t just helping the planet—they’re future-proofing their operations.

Sustainable supply chains are often more stable, less wasteful, and more attractive to investors, customers, and employees alike.

9. Monitor Regulations and Compliance

Global trade is like walking a legal tightrope. One regulation change can throw your supply chain off balance.Stay informed about customs laws, tariffs, trade agreements, and environmental regulations—especially in your major sourcing regions.

Partnering with legal experts or trade consultants can help you stay compliant and avoid nasty surprises.

10. Continuously Improve (Kaizen for the Win)

Building a resilient supply chain isn’t a one-and-done deal. It’s something you revisit constantly.Adopt a mindset of continuous improvement. Run audits. Gather feedback. Track KPIs. Look for weak spots, and upgrade them.

The best businesses treat their supply chains like living organisms—they adapt, evolve, and always look for better ways to operate.

Real Talk: Is Resilience Worth the Investment?

Let’s not sugarcoat it—building a resilient supply chain takes time, money, and effort.But think of it like insurance. When disaster strikes (and at some point, it will), you’ll be better positioned to survive—maybe even thrive—while your competitors scramble.

Plus, a resilient supply chain also usually means:

- Faster response times

- Less waste

- Better customer satisfaction

- Lower long-term costs

- Fewer sleepless nights

And who doesn’t want that?

Wrapping It Up

Your supply chain might not be flashy, but it’s the lifeline of your business. Without it, you’ve got nothing to sell, nothing to deliver, and no customers to serve.Building resilience isn’t just a nice-to-have—it’s a must-do if you want to protect your business against an unpredictable world.

So, take the time. Invest the resources. Build something sturdy, flexible, and unshakeable.

Because when the next disruption hits—and trust me, it will—you’ll be ready.

all images in this post were generated using AI tools

Category:

EntrepreneurshipAuthor:

Matthew Scott

Discussion

rate this article

2 comments

Finn McPhail

This article raises fascinating points about supply chain resilience! I'm curious about the specific strategies that have proven most effective in real-world applications. How do successful companies measure the impact of their resilience initiatives?

June 14, 2025 at 12:22 PM

Matthew Scott

Thank you for your feedback! Successful companies often employ strategies like diversification of suppliers, investing in technology for real-time tracking, and building strong relationships with partners. They measure impact through key performance indicators (KPIs) such as lead time reduction, cost savings, and customer satisfaction metrics.

Astoria Ward

Building a resilient supply chain is not just about managing risks; it's an opportunity to innovate and strengthen your business foundation. Embrace challenges as stepping stones to growth, and remember that adaptability is key. Together, we can navigate uncertainties and emerge stronger than ever! Keep pushing forward!

June 14, 2025 at 4:35 AM

Matthew Scott

Thank you for your insightful comment! I completely agree—embracing challenges and fostering adaptability are essential for building a resilient supply chain that drives innovation and growth. Let’s keep pushing forward together!